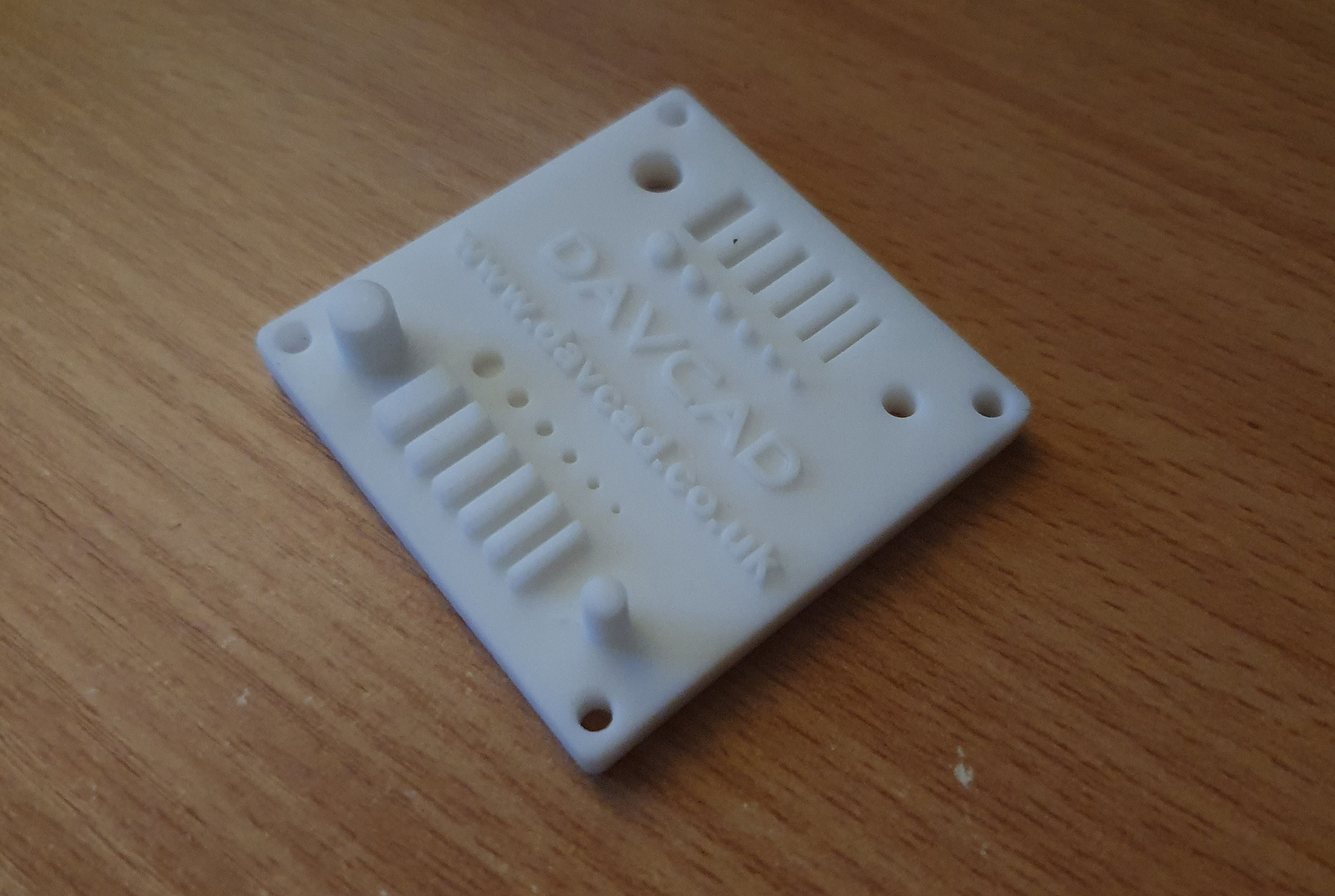

DAVCAD

CAD DRAUGHTING SERVICES

- 3D Printing

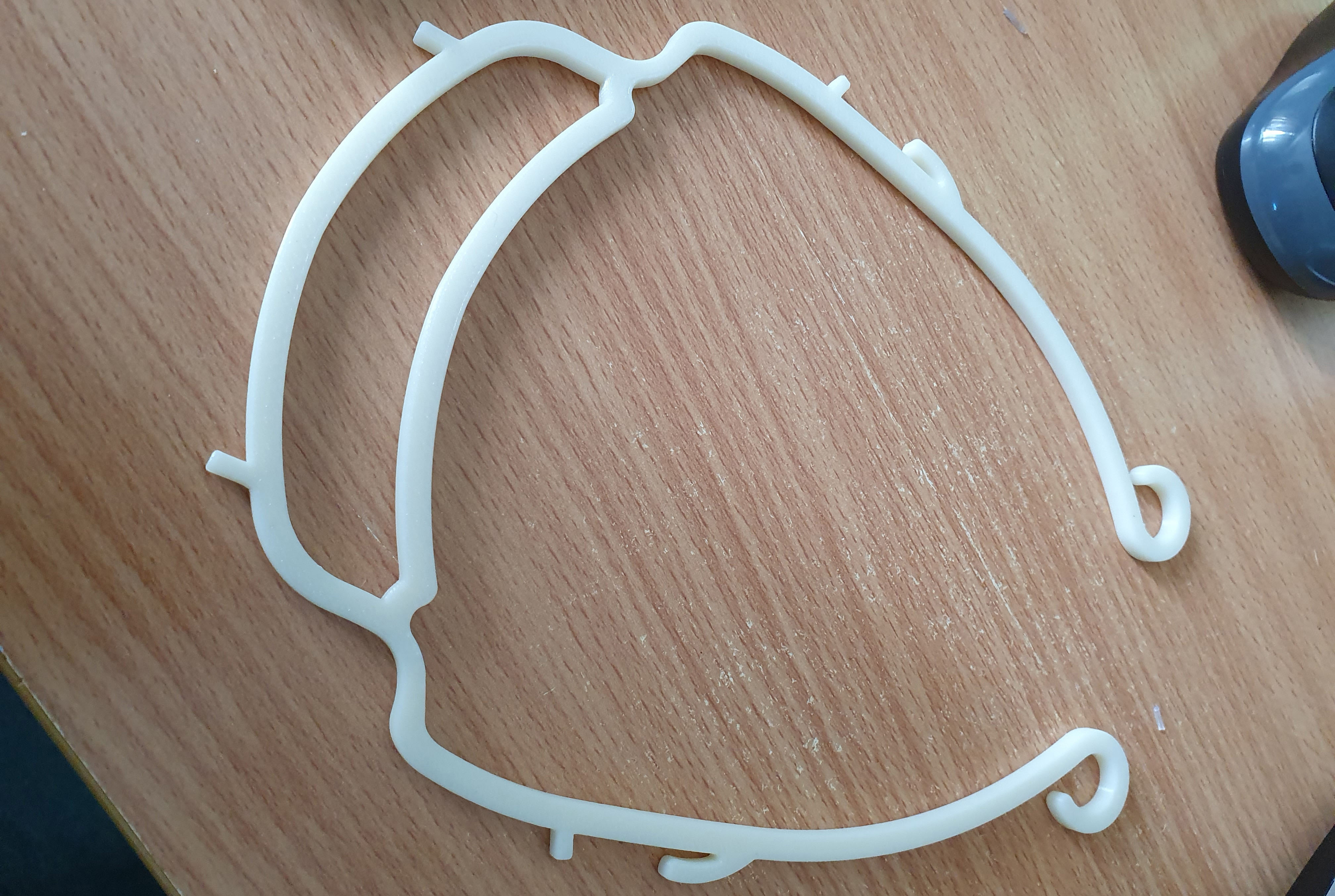

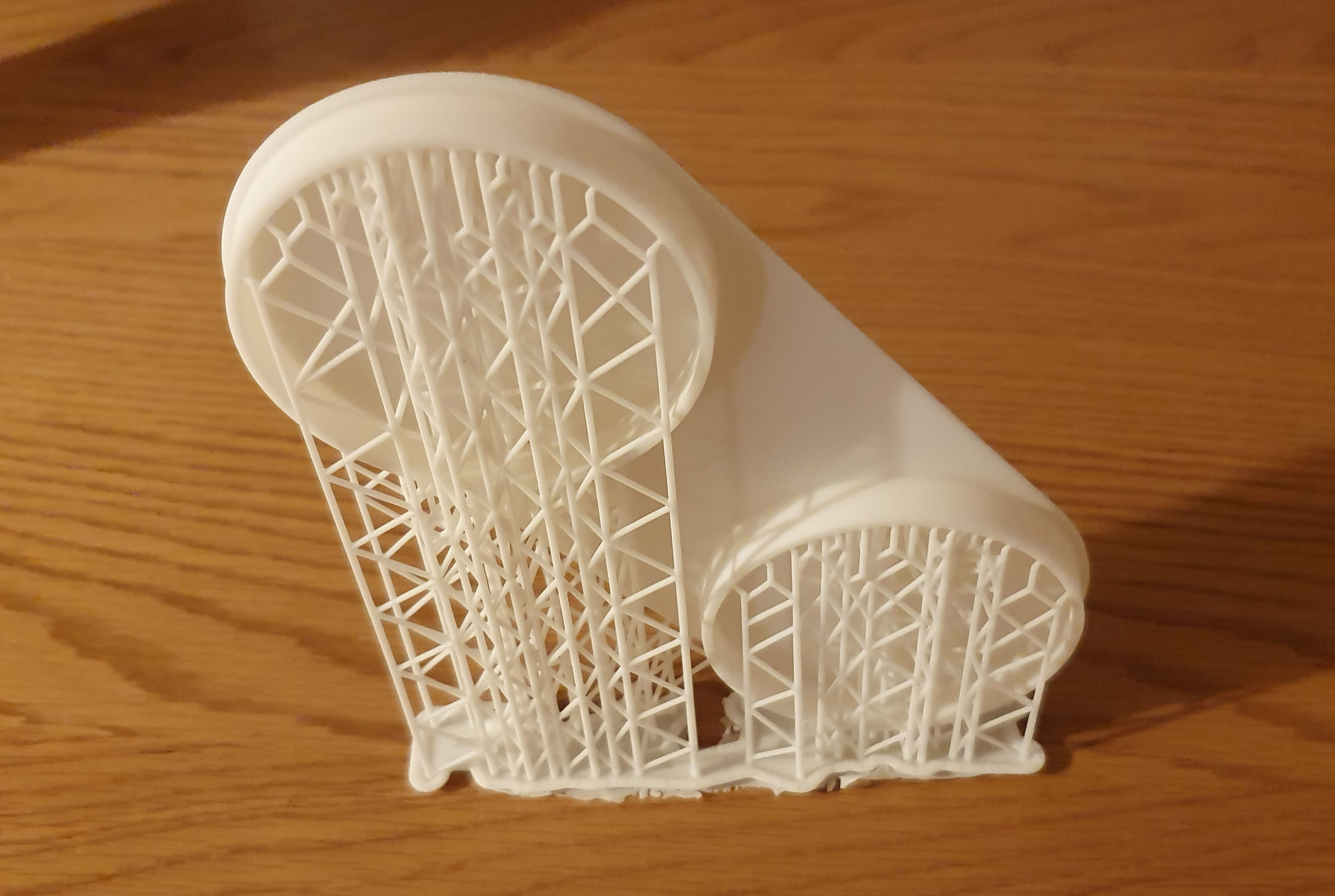

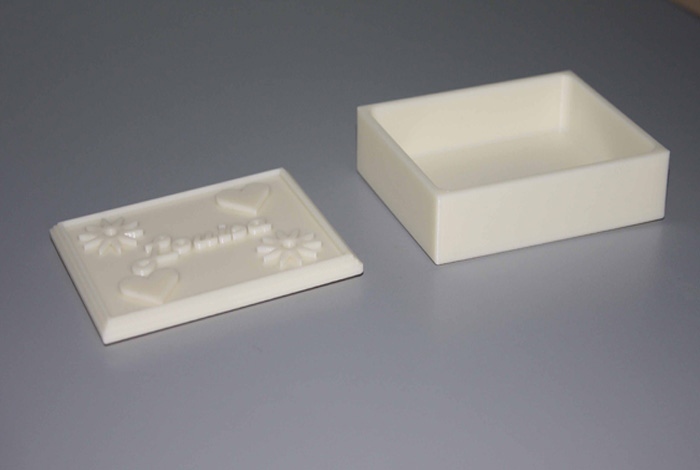

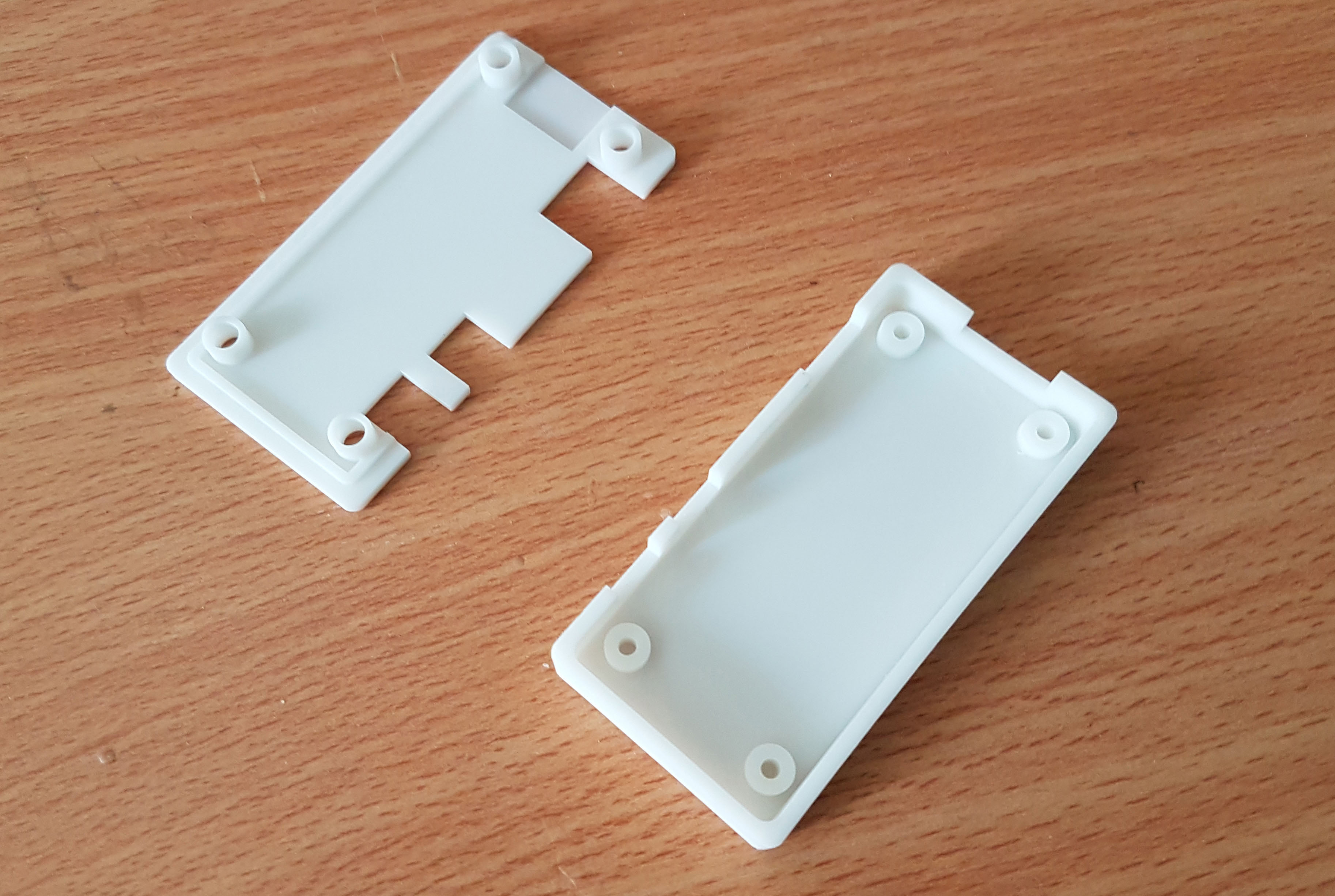

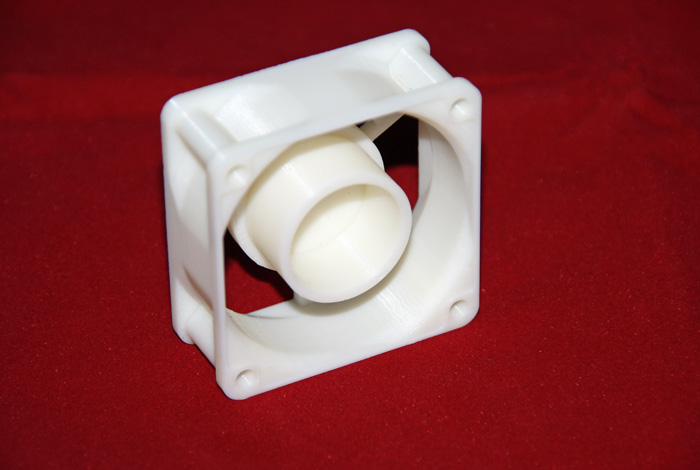

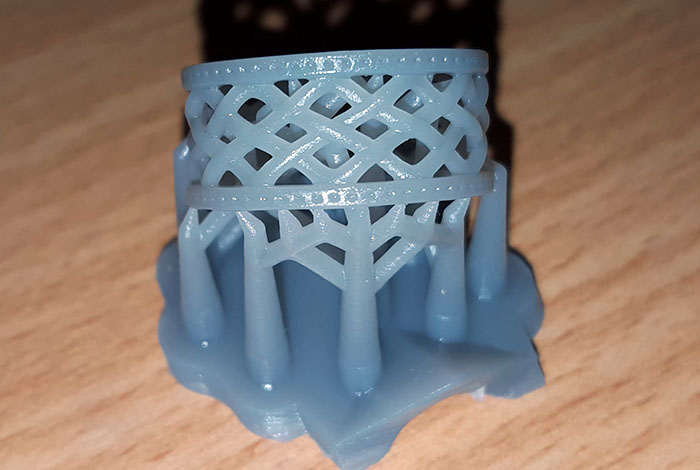

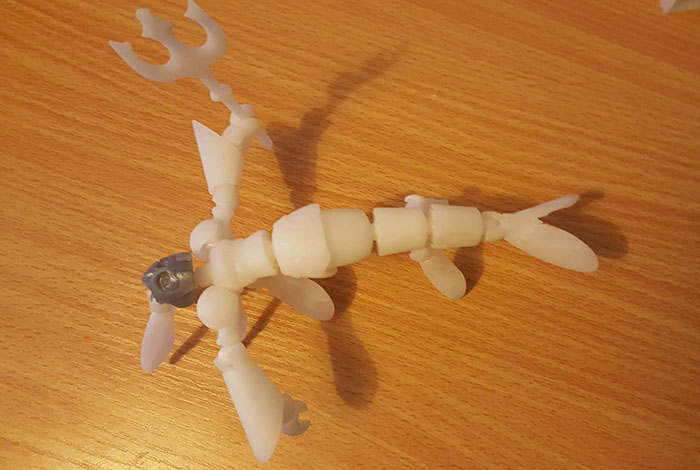

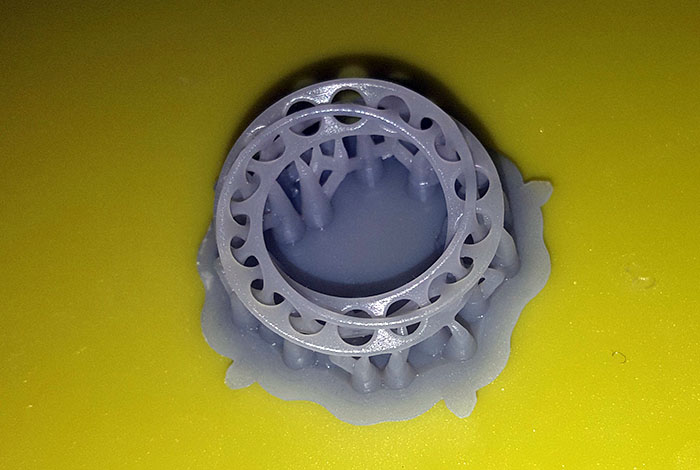

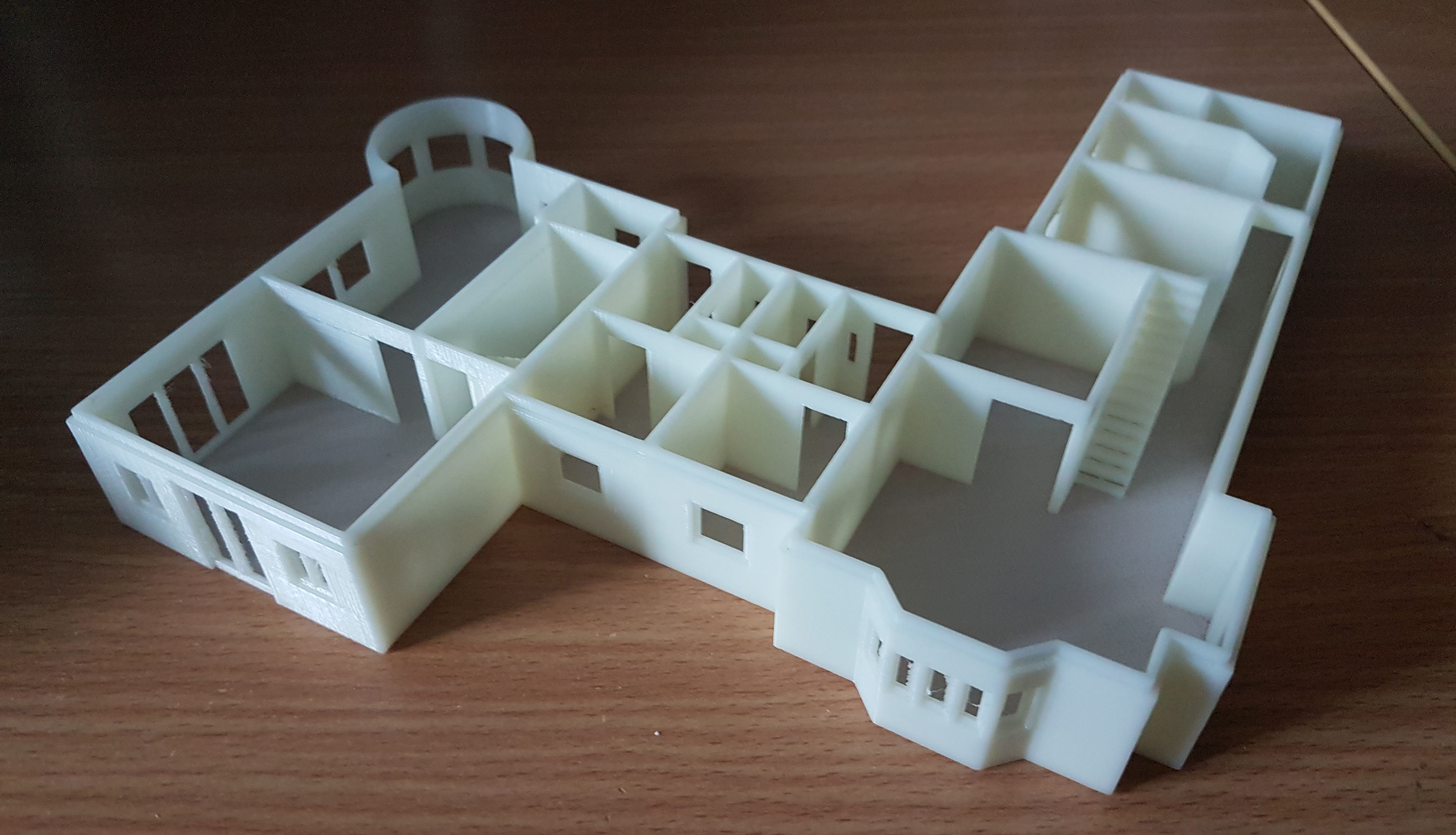

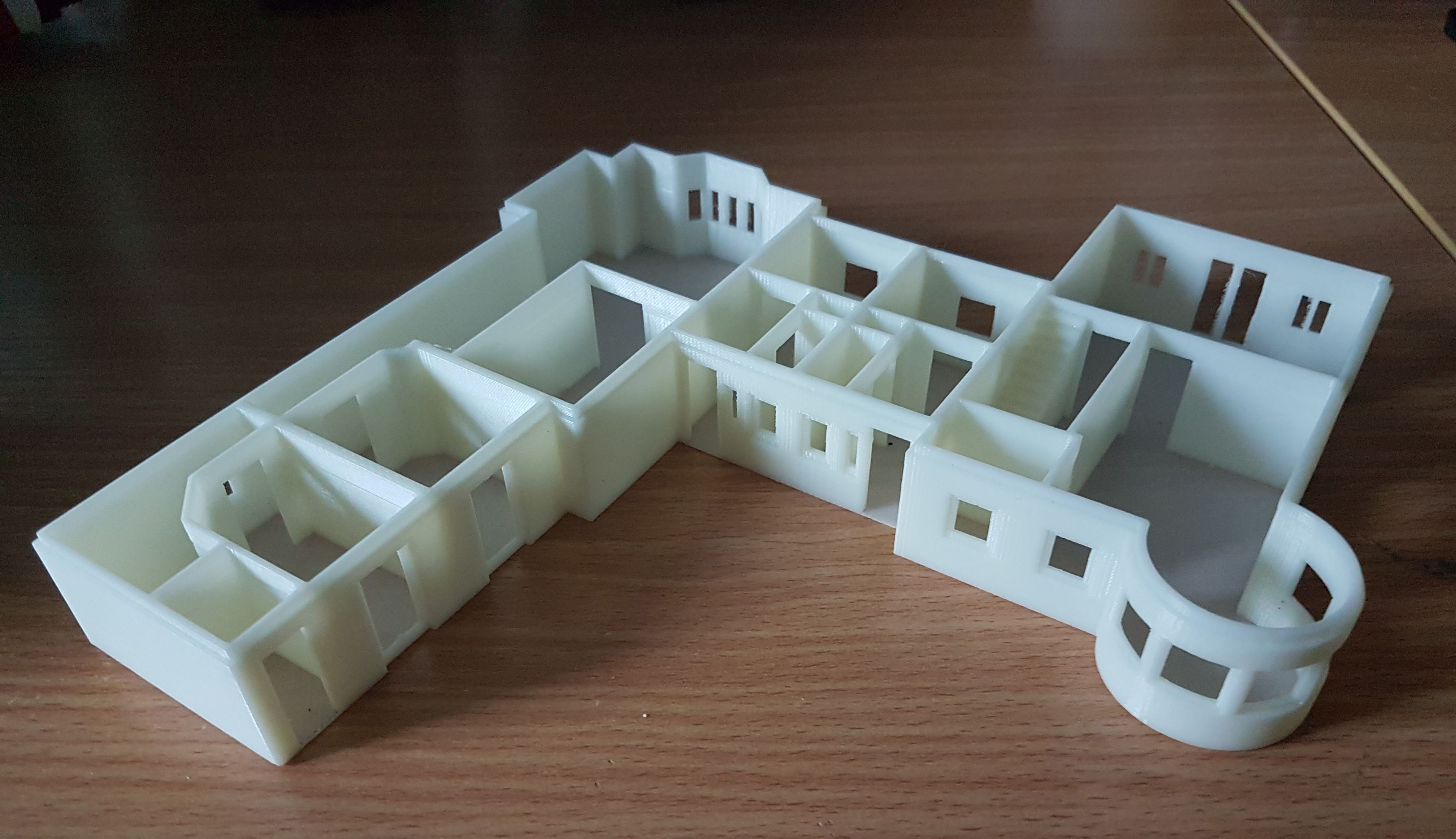

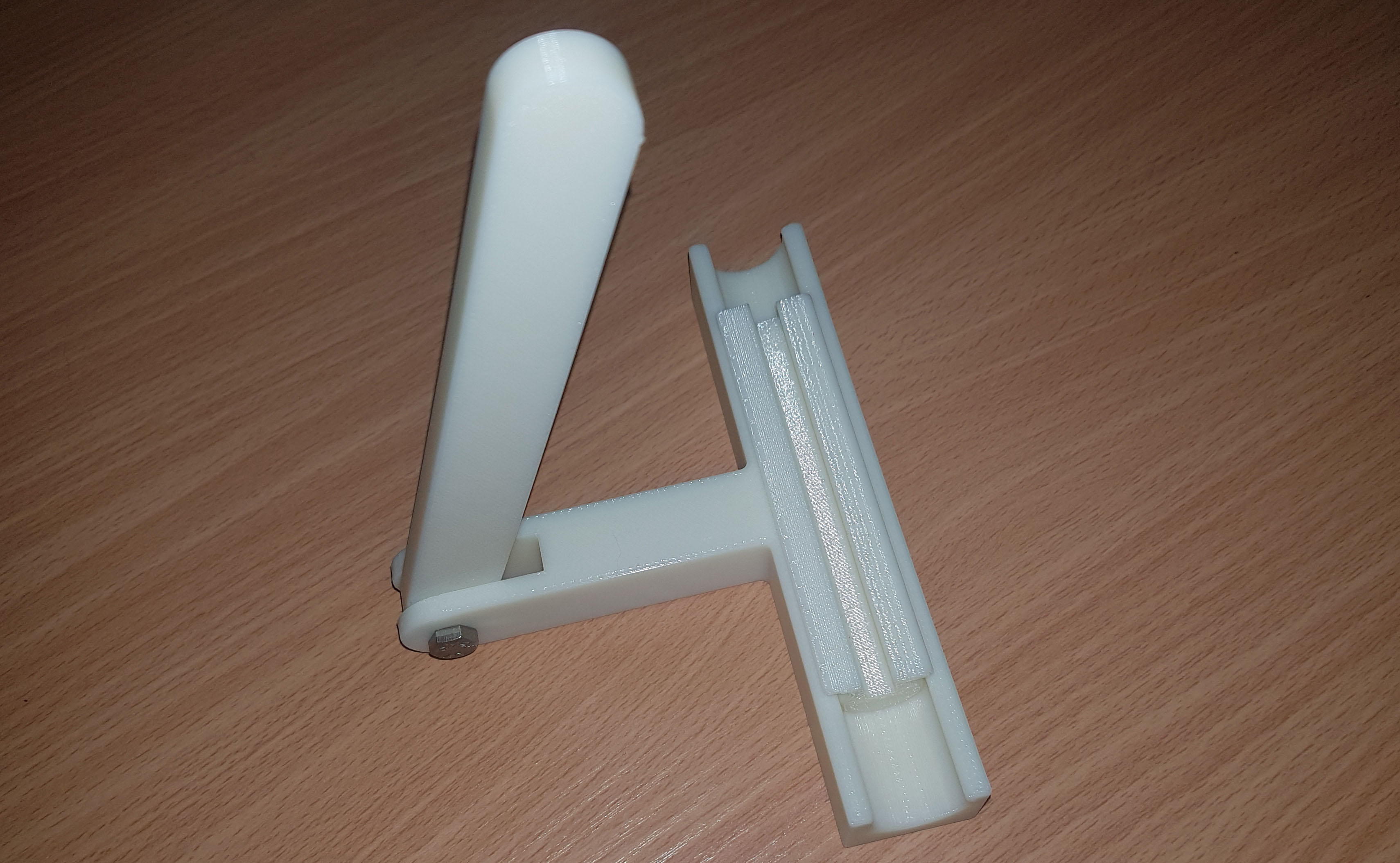

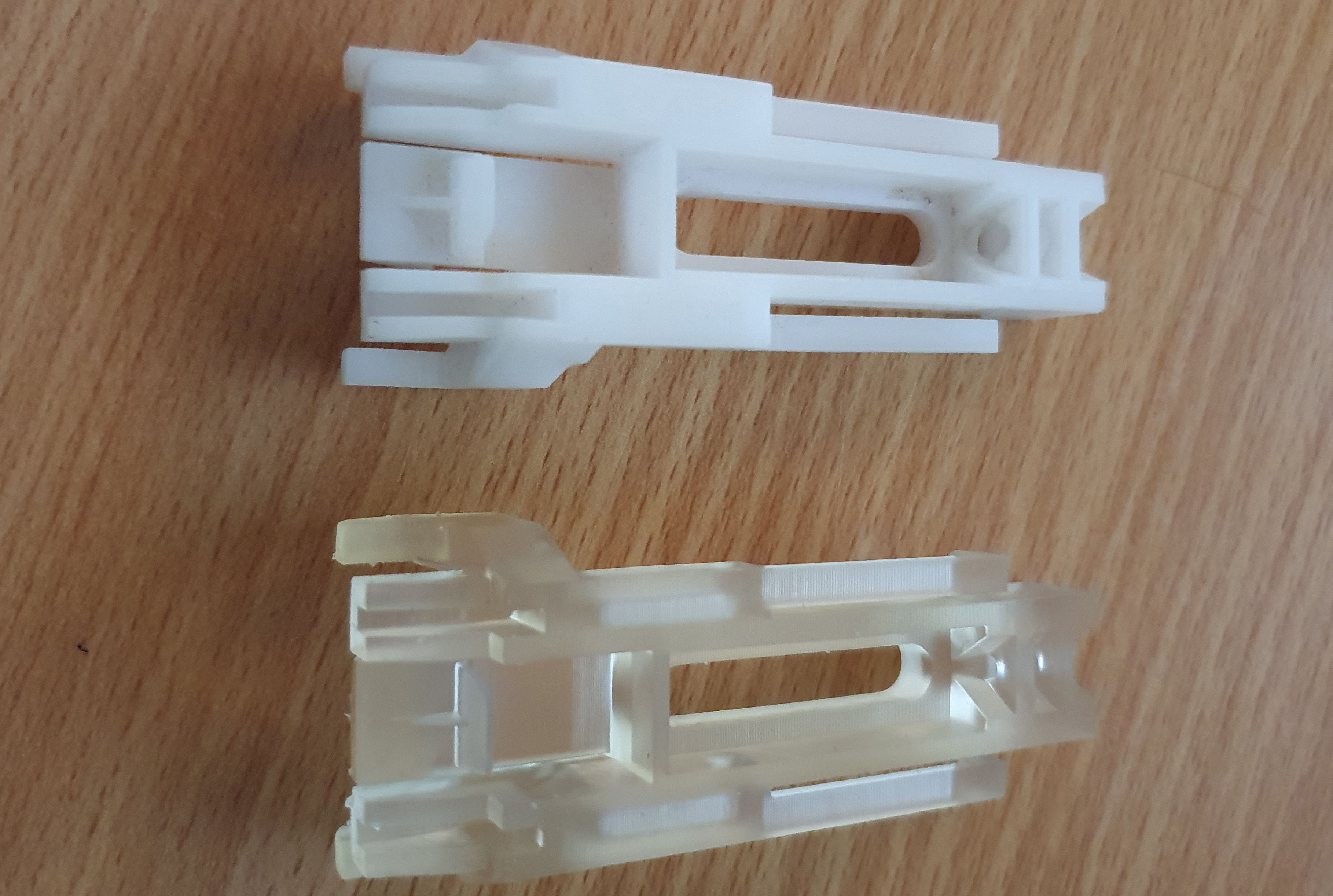

DAVCAD utilises an HP 3D Designjet Printer and Formlabs Form 2 SLA Printer to produce 3D printed models. The HP Designjet uses a specialised ABS material which is 40% stronger than normal ABS. Models produced with the HP Designjet Color 3D Printer are durable and precise, allowing clients to see accurate conceptual models within hours rather than days and weeks using traditional methods. Saving time and the expense of producing high cost prototypes to evaluate. The models can also be functional, therefore models can be assembled to produce a fully working model to test the form, fit and function of a design. They can also be painted, machined, drilled and even chrome plated to give a more visual effect. The Formlabs Form 2 Printer offers additional materials and also very fine detail utilising a minimum layer thickness of 20µm. Again these prints can be painted, machined, drilled along withstanding different operating conditions depeding on the material used.

HP Designjet 3D Colour Printer:-

Specifications:-

Build size (w x d x h) 203 x 203 x 152 mm (8 x 8 x 6 in)

Layer thickness 0.01 in (0.254 mm) or 0.013 in (0.33 mm)

Model material colors 8 (Ivory, Black, Red, Olive Green, Nectarine, Fluorescent Yellow, Blue and Gray)

Automated support removal using the HP Designjet 3D Removal System

Software features Automatic real-time support structure generation with SMART supports (which minimizes the amount of support material used, reduces the build time, and improves support removal time for many parts); auto-orientation which determines the best orientation for your model for the fastest build time and least material usage; model density options (Solid, Sparse High Density, Sparse Low Density).

HP Designjet Support Removal System:-

The HP Designjet 3D Removal System partners with the HP Designjet 3D printer to remove supports from the models automatically. The solution is designed to be used in an office environment, thus special disposal methods or equipment are not typically required. A fully enclosed detergent is utilised in the HP Designjet 3D Support Removal Powder Kit so you can handle it without gloves. The HP Designjet 3D Removal System removes the supports from your models automatically without creating a mess and saving you time making it an ideal solution for the office environment.

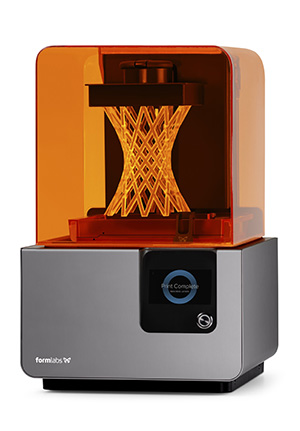

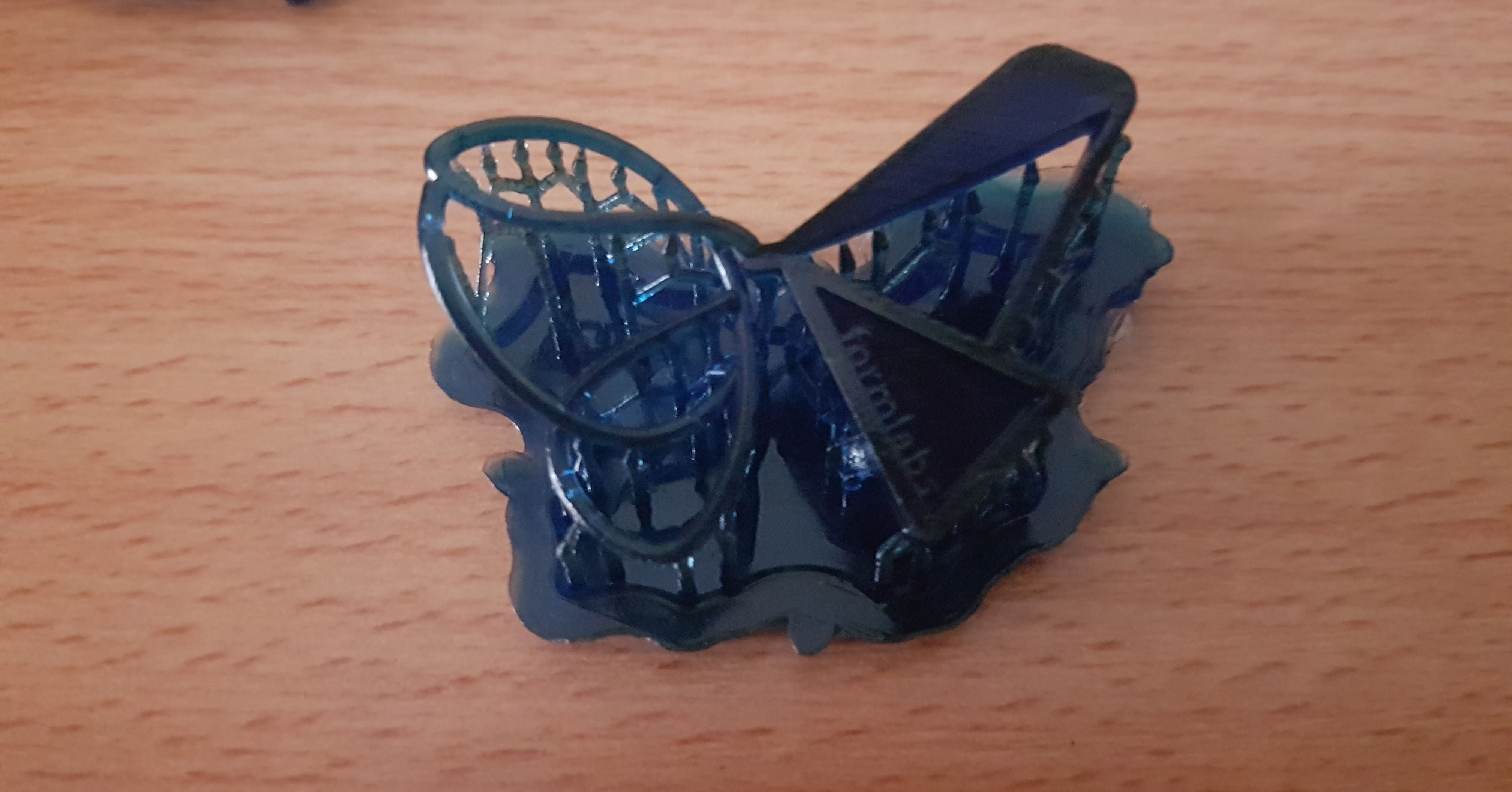

Formlabs Form 2:-

Specifications:-

Build size (w x d x h) 145 x 145 x 175 mm (4.9 x 4.9 x 6.5 in)

Layer thickness 25, 50, 100 and 200 microns (Not all materials available at all layer thicknesses - Please ask for specific requirements)

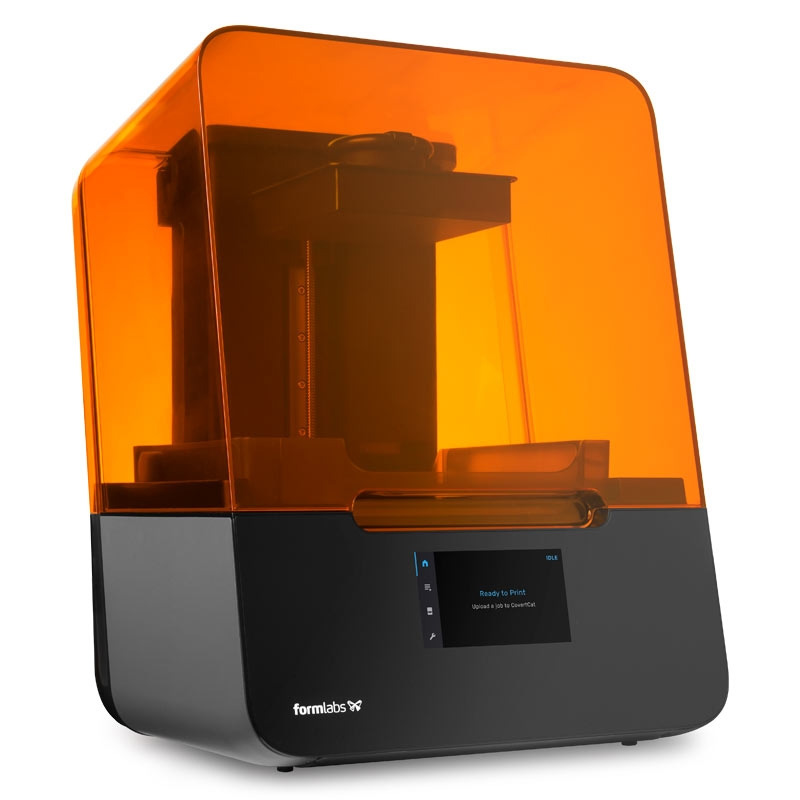

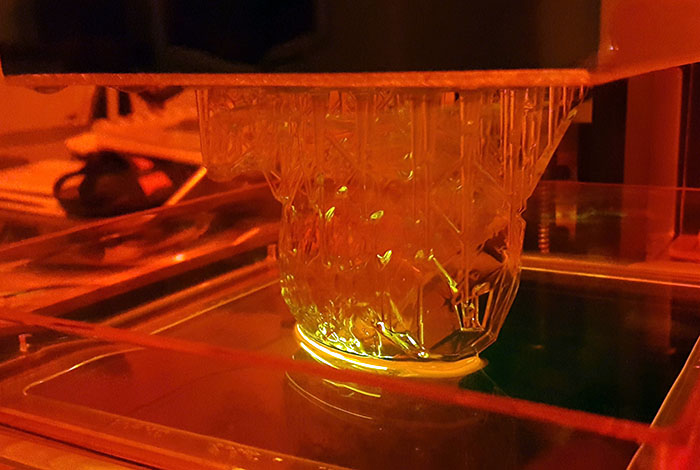

Formlabs Form 3:-

Specifications:-

Build size (w x d x h) 145 x 145 x 185 mm (4.9 x 4.9 x 7.2 in)

Layer thickness 25, 50, 100 and 200 microns (Not all materials available at all layer thicknesses - Please ask for specific requirements)

Using Low Force Stereolithography (LFS)™ uses a flexible tank and linear illumination to deliver better print quality and printer reliability

Model materials (Formlabs Form 2 and 3) :-

- Resin Overview

- Clear Resin

- Black Resin (same material properties as Clear Resin)

- Grey Resin (same material properties as Clear Resin)

- White Resin (same material properties as Clear Resin)

- Colour Base (same material properties as Clear Resin - Special Order)

- Colour Pigment (same material properties as Clear Resin - Special Order)

- Grey Pro Resin

- Rigid Resin

- Castable Resin (Special Order)

- High Temperature Resin

- Flexible Resin

- Elastic Resin

- Tough 1500 Resin

- Tough 2000 Resin

- Durable Resin

- Dental SG Resin (Special Order)

- Dental LT Clear Resin (Special Order)

- Dental Model (Special Order)

- Dental Surigcal Guide (Special Order)

- Digital Dentures (Special Order)

- Draft Resin

- Ceramic Resin (Experimental Product Only)

Manual Support Removal

Software features :

- Simple print setup

- Auto-orient for optimal print position

- Auto-mesh repair

- Auto-generation of supports

- Rotation, scaling and duplication

- Layer slicer for path inspection

- .STL and .OBJ file input